market@chinacoalintl.com

The measurement methods of the reabr detector are mainly divided into automatic measurement, manual measurement, and minimum protective layer thickness measurement. The specific detection of each method is summarized as follows:

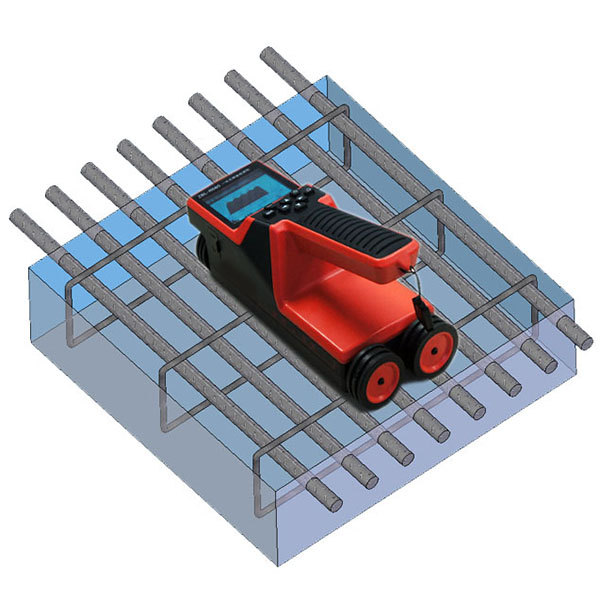

● Automatic measurement

The sensor runs parallel to the steel bar and sweeps over the steel bar at a constant speed. The instrument emits a beep to remind the sensor to cross a steel bar. At this time, the protective layer display value is automatically updated to the protective layer thickness value there.

How To Use The Rebar Detector?

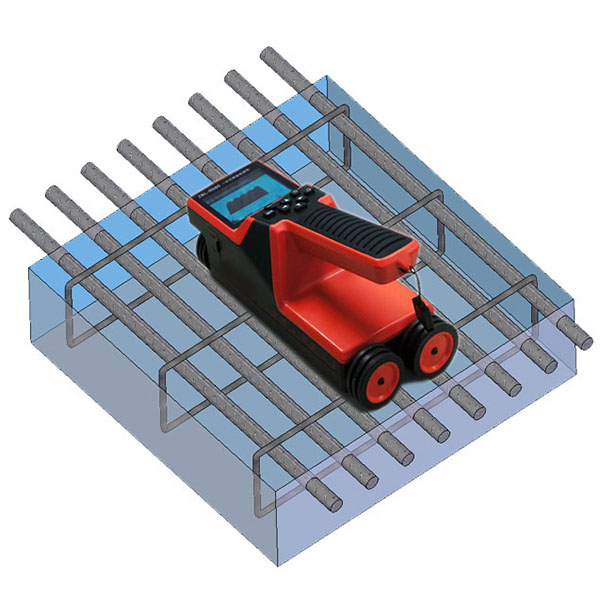

● Manual measurement

The distance between the steel bars is smaller than the situation described in the above table, and the thickness of the protective layer must be determined by manual measurement.

The sensor is parallel to the direction of the steel bar, sweeping over the top of the steel bar at a uniform speed, and the thickness value of the protective layer is determined according to the change of the current distance display value and the signal value.

● Minimum protective layer thickness measurement

This function is mainly used in the following occasions:

1. Quickly check whether the thickness of the concrete protective layer meets the minimum design value, and alarm the abnormal point;

2. After the formwork is removed, check whether the steel bar is stretched out.

Have you mastered the detection methods of the above three rebar detectors? For more about the measuring method of the rebar detector, please feel free to leave a message with us online! !

© Shandong China Coal Group. © 2017

Address: No. 11, North of Kaiyuan Road, High-tech Zone, Jining City, Shandong Province, China

sales@chinacoalintl.com

Executive Editor: Zhang Wen / Editor: Linda Zhang