market@chinacoalintl.com

The reinforced concrete members are the main members of the concrete structure. The bearing capacity of the reinforced concrete members is mainly controlled by the section size, the effective height of the section, the strength of the concrete and steel bars, and the amount of reinforcement. Obviously, under the condition of the section size and the concrete strength, the bearing capacity of the reinforced concrete members is controlled by the strength of the steel bars, the effective height of the sections and the amount of reinforcement.

At the same time, the durability of reinforced concrete members is mainly controlled by the quality of the concrete and the thickness of the reinforced concrete cover.

During the service of concrete structures, due to the influence of environmental effects or disasters, the steel bars may also show signs of deterioration such as corrosion, which not only reduces the cross-section of the steel bars, reduces the mechanics of the steel bars, but also reduces the bonding properties of steel bars and concrete, and weakens the steel bars and concrete. The basis for working together.

Steel bar inspection project in concrete

Number and spacing of steel bars, thickness of concrete protective layer, diameter of steel bars, mechanical properties of steel bars, corrosion of steel bars, stress state of steel bars

Detection method

1, non-destructive detection method 2, magnetic induction method 3, radar method 4, chisel in situ detection 4, sampling detection

Today China coal editor mainly takes everyone to understand the magnetic induction method.

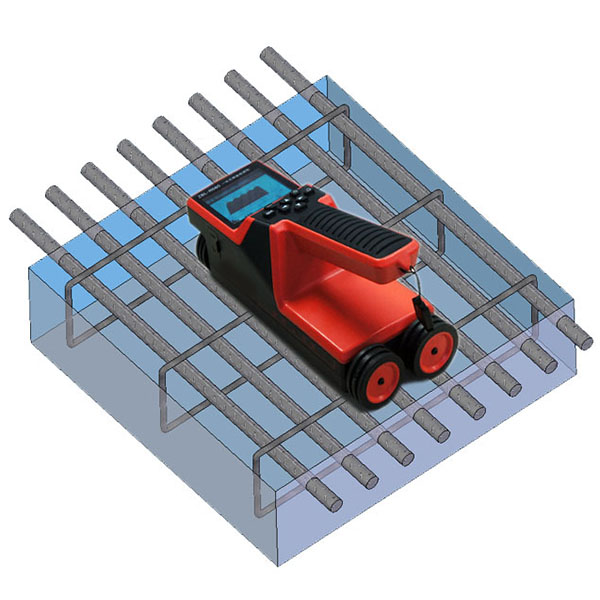

Principle: The rebar detector consists of two parts: the probe and the main unit. The working principle of the probe part is electromagnetic pulse. Two sets of coils are mounted inside the probe, one set is a magnetic field coil and the other set is an induction coil. The magnetic field coil produces a high-pulsing primary electromagnetic field in the concrete to be inspected. If there is a metal object in the concrete, the object will induce a secondary electromagnetic field (located within the first electromagnetic field described above). The pulse gap of the electromagnetic field generated by each field coil causes the attenuation of the second electromagnetic field, which causes the induction coil to produce a voltage change. Therefore, according to the change of this voltage, the steel distance and the thickness of the protective layer in the concrete are obtained by mathematical calculation.

Compared to the other three methods, the advantages of the rebar detector are as follows:

1.Visual fine scan mode, contour scan mode, grid scan mode ensure correct measurement of data and rapid generation of test results;

2.Accurately detect the position, spacing, direction and distribution of the reinforcement (grid);

3.Accurate measurement of concrete cover and steel bar diameter;

4.Automatically save data such as position, spacing, diameter, distribution and concrete cover of the reinforcement.

5.Display component number, scan data, statistics and reinforcement distribution (fine, contour and grid);

6.Test data can be transmitted to the computer through the USB port for real-time analysis of data;

7.Soft backlight for use in low light conditions;

8.Rechargeable lithium battery; convenient, value for money, environmentally friendly.

© Shandong China Coal Group. © 2017

Address: No. 11, North of Kaiyuan Road, High-tech Zone, Jining City, Shandong Province, China

sales@chinacoalintl.com

Executive Editor: Zhang Wen / Editor: Linda Zhang