market@chinacoalintl.com

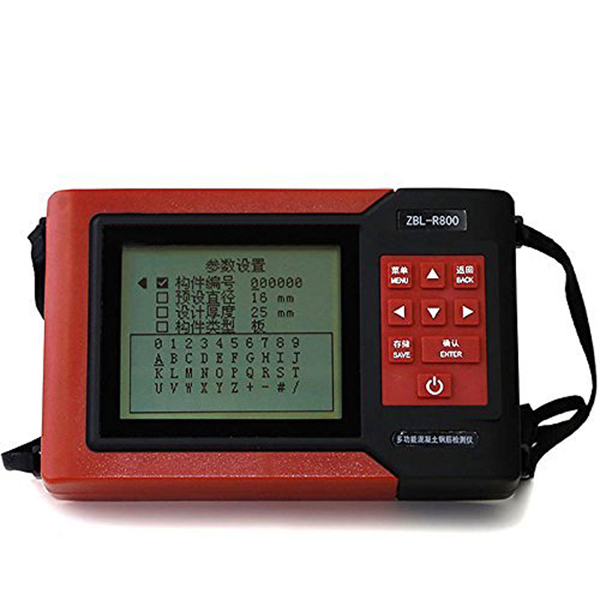

Many people do not understand the correct use of rebar detector in concrete, resulting in inaccurate final results. Today, I summarized the following points for the use of rebar detector in concrete for reference:

1 During the rebar detector in concrete operation, the instrument should be handled gently and strictly in accordance with the instrument operating procedures.

2 During the rebar detector in concrete process, the steel joints should be avoided. When the difference between the thicknesses of the two concrete protective layers read at the same location is greater than 1 mm, the test data of the group is invalid, and the cause is identified and re-tested there. If the requirements are still not met, the rebar detector in concrete should be replaced or verified by drilling and chiseling.

3 The detection process can be detected by adding a spacer under the probe.

4 The moving speed of the probe should not exceed 2cm/s. Try to keep moving at a constant speed to avoid moving in the opposite direction before finding the steel bar. Otherwise, it will cause large detection error or even leakage.

5 If the continuous working time is long, in order to improve the detection accuracy, it should be noted that the probe is taken to the air every 5 minutes, away from the metal, press the confirm button to reset. If there is any objection to the test result, this can also be done.

6 Set the diameter of the steel bar correctly, otherwise it will affect the rebar detector in concrete test result.

© Shandong China Coal Group. © 2017

Address: No. 11, North of Kaiyuan Road, High-tech Zone, Jining City, Shandong Province, China

sales@chinacoalintl.com

Executive Editor: Zhang Wen / Editor: Linda Zhang